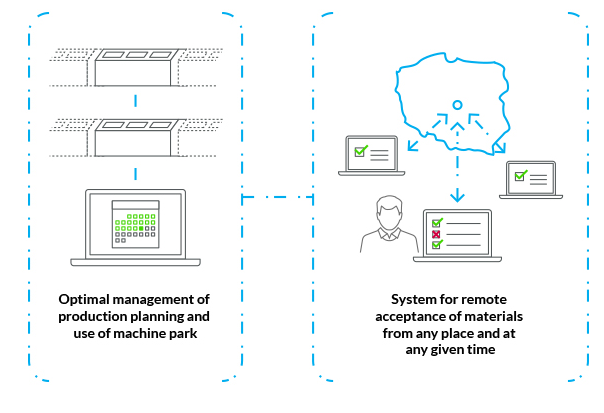

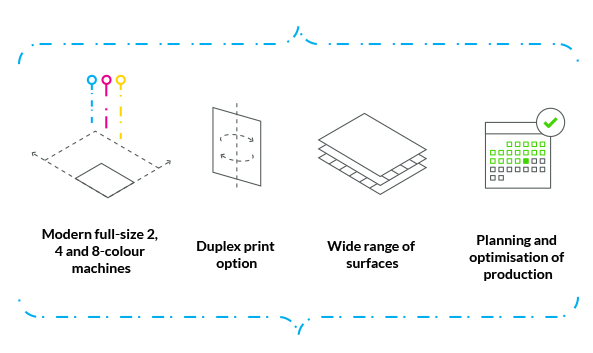

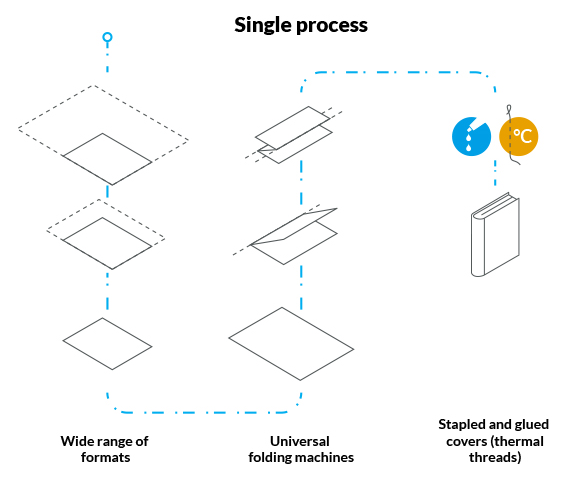

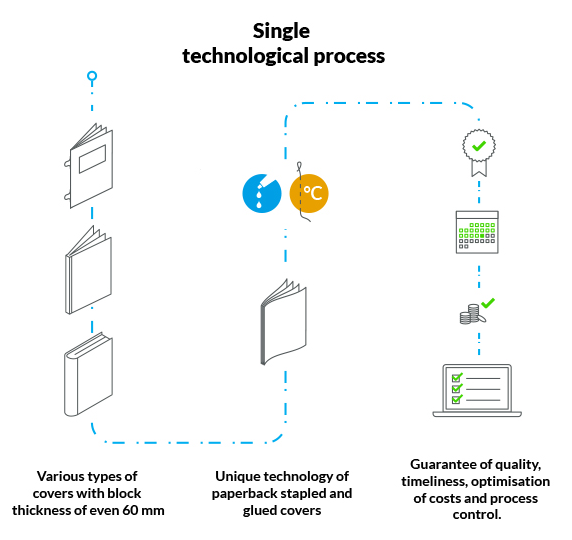

MEETING EXPECTATIONS OF OUR CUSTOMERS

in terms of the price, safety, timeliness and quality of our products would be impossible without the use of appropriate technologies and machines and devices associated with them. Therefore, we do our best to properly adapt our machine park to the nature of implemented orders, thus ensuring a high quality of optimisation of production process, in particular in terms of lowering the costs on every stage of execution of an order.